Introduction

Hydrogen is an energy carrier and therefore, Fuel Cells and Hydogren (FCH) technologies will play a key role in the future European energy scenario based on renewable energy (in which its management will be a crucial factor). It will be possible to generate vast amounts of “green” hydrogen from the expected surplus of renewable energy sources and subsequently use it in transport (fuel cells to power vehicles), energy applications (feeding stationary fuel cells for cogeneration, injecting hydrogen into the gas grid, back-up systems, etc.) and industrial applications (hydrogen generation mainly for chemical industries).

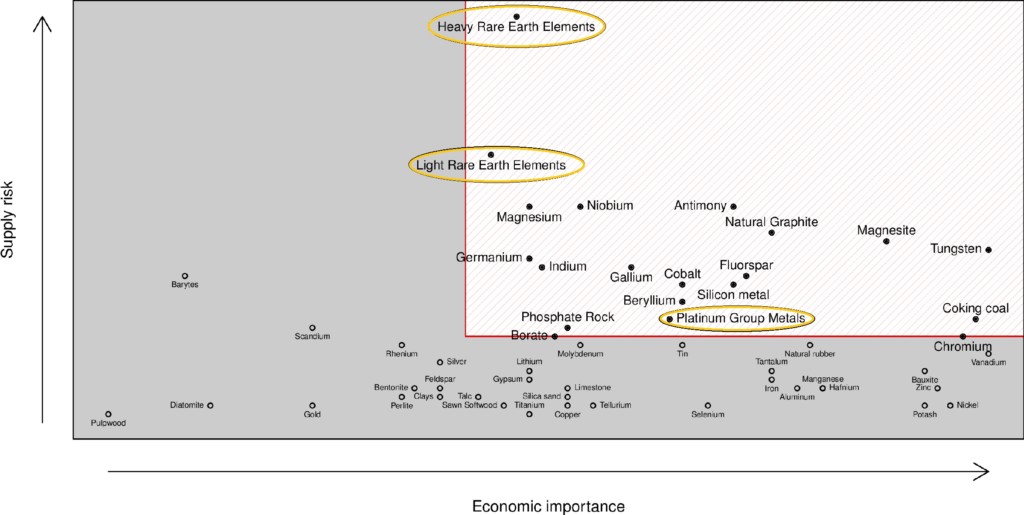

Critical materials according to the European Comission standards based on economic importance and supply risk. SOURCE: European Comission (EC)

However, the expected commercial FCH technology deployment (mainly PEM and alkaline electrolysers as well as PEM and Solid Oxide fuel cells) must take recycling and dismantling into account, as well as possible end-of-life uses. It should be borne in mind that these devices contain significant amounts of critical, expensive and scarce materials necessary [FHA1] for their operation. Metals from the platinum group (PGM) and rare earth elements are used in fuel cells and electrolyser catalysers, electrodes and electrolytes. Both groups are identified by the European Commission as critical materials that must be reduced or replaced.

Furthermore, there is a lack of end of life strategies devoted to reuse and remanufacture FCH technologies in order to save raw materials and take advantage of still valuable components and subsystems. It is especially important to implement innovative recycling processes involving both FCH technologies manufacturers (through the redesigning of products to facilitate greater recovery of critical materials and greater compatibility with recycling and dismantling) and end users, in order to ensure collaboration and supply of products within a methodological framework of reverse logistics.